Unit 7, Minto Place, Altens, Aberdeen AB12 3SN

The Hub, Hareness Road, Altens, Aberdeen AB12 3LE

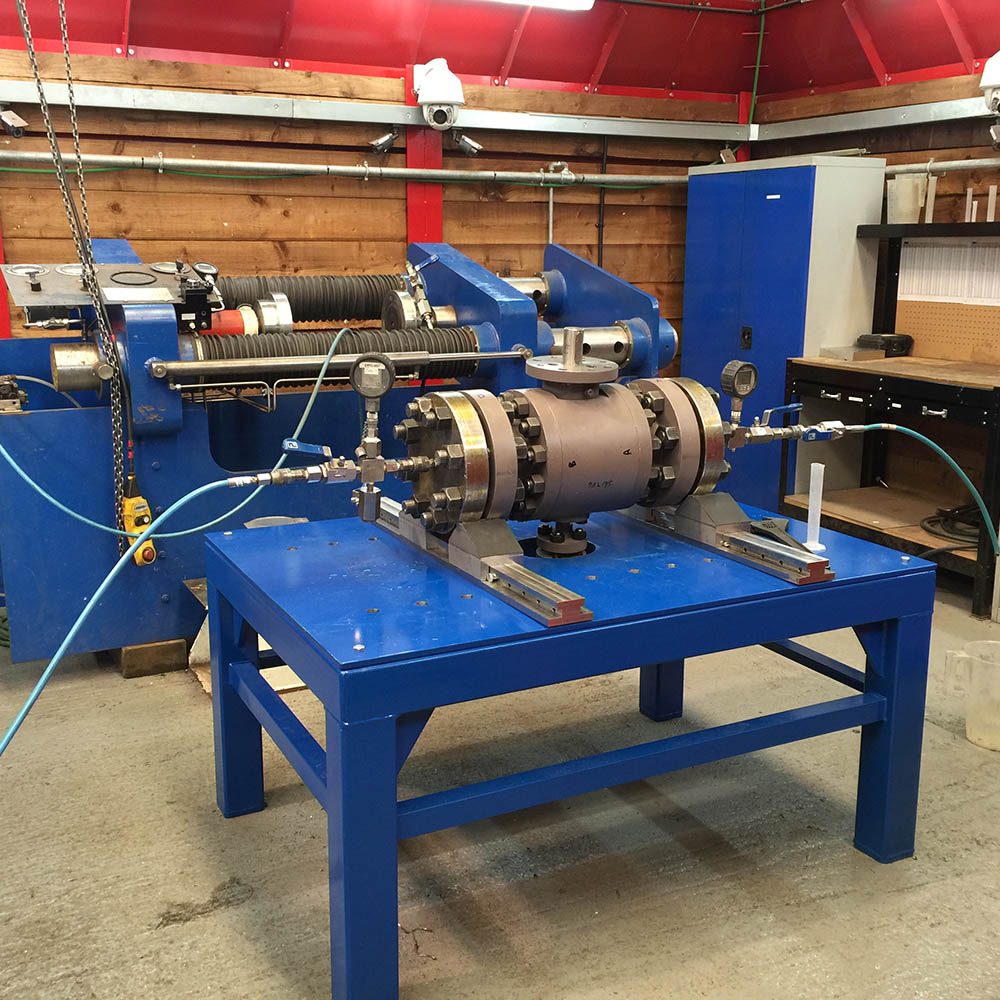

X5 Test bays:

X1 Control, choke, gate, check, and globe test facility:

X1 General test facility:

X2 PSV test facilities:

X1 Mixing kitchen:

X1 Painting Facility 6M x 6M:

X1 Drying Room:

X2 Blast rooms

X1 Colchester Triumph 2000 lathe:

X1 Dean Smith Grace lathe:

X1 Webster Bennet Vertical Borer:

X1 Webster Bennet Horizontal Borer:

X1 Bridgeport Milling & Slotting Machine

X1 Large Pedestal Drill:

X1 Small Pedestal Drill:

X1 Fabrication Area:

Assembly Area:

X2 Control & Choke valves bays:

X1 Large valves bay:

Disassembly Area:

X1 Small area:

X2 Large Storage Shelves (16 Pallets each):

X1 Kardex Machine:

Fork Lift Trucks:

Compressors:

X1 Atlas Capco

X1 Atlas Capco

X1 Atlas Capco

Warehouse:

Summary:

Free 24-hour Helpline: call our team today on

01224 583116